Dried Fish Packaging Machine

Get Latest Price| Min. Order: | 1 |

The file is encrypted. Please fill in the following information to continue accessing it

Our Dried Fish Packaging Machine is designed specifically for seafood processors who need high-efficiency, hygienic, and long-lasting packaging solutions for dried fish, dehydrated seafood, and related products. This machine integrates automatic weighing, filling, sealing, and date coding to ensure stable production and consistent pack quality for both small and medium-sized factories as well as large-scale processing facilities.

Dried fish products often come with unique challenges: uneven shapes, sharp edges, varying densities, and a higher tendency to cause bag punctures if the package material or sealing strength is insufficient. To solve these industry-specific pain points, our packaging system is engineered with reinforced components, enhanced sealing technology, and optimized product-feeding structures. These improvements significantly reduce packaging defects and improve the overall shelf appearance and reliability of your finished goods.

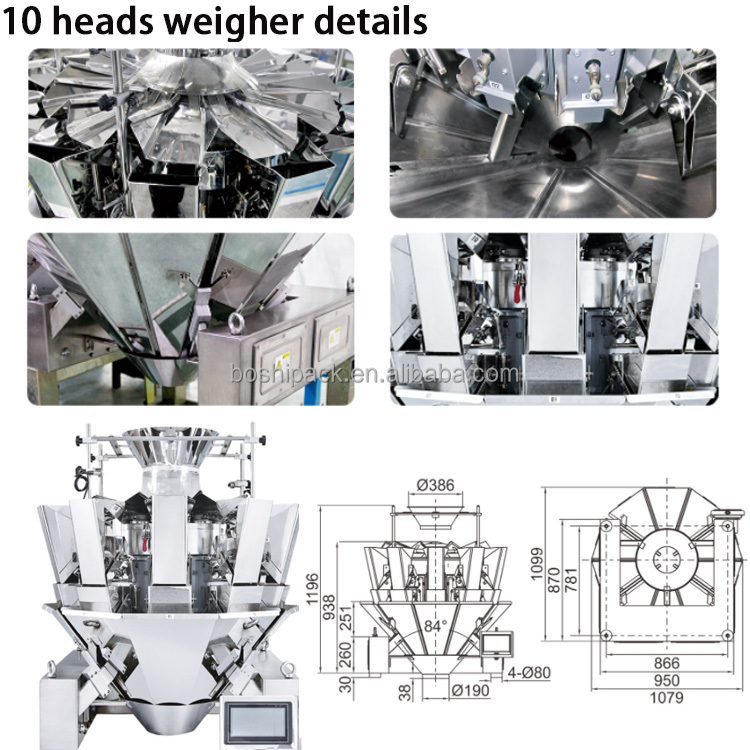

At the core of the system is a precision-controlled electronic weighing unit that ensures accurate product dosing. Whether your product is small dried anchovies, shredded dried squid, fish strips, or whole dried fish fillets, the machine can handle each type with high accuracy and minimal product damage. The vibration feeding channels and adjustable hopper angles ensure smooth feeding without clogging or product breakage, which is especially important for fragile dried seafood varieties.

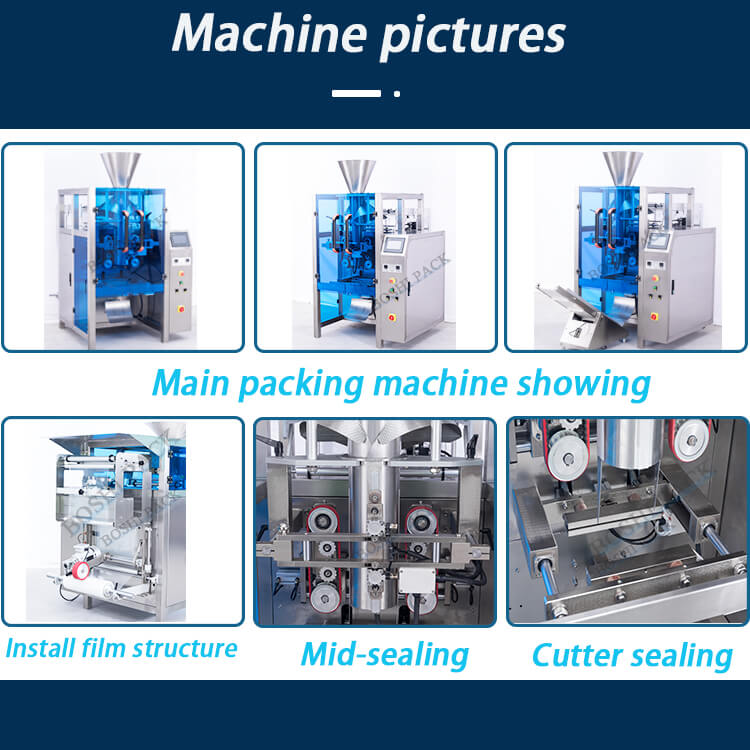

The machine uses an advanced vertical form-fill-seal (VFFS) or premade pouch system (depending on the configuration you choose). The VFFS system automatically forms bags from roll film, while the premade pouch system works with stand-up pouches, zipper pouches, flat pouches, and aluminum laminated bags. Both systems support high-barrier packaging materials to protect dried fish from moisture, oxidation, and loss of flavor.

For businesses selling dried seafood to supermarkets, international markets, or e-commerce channels, the machine helps maintain a clean and premium packaging appearance. The strong sealing mechanism produces tight, wrinkle-free seals to extend product shelf life. Optional nitrogen flushing removes excess oxygen inside the pack, helping maintain product color, aroma, and long-term freshness.

The system is built with food-grade stainless steel throughout, ensuring hygiene, durability, and compliance with export-oriented production standards. All parts that come into contact with food are corrosion-resistant and easy to clean, minimizing downtime between production batches. Operators can switch products and packaging sizes quickly thanks to a user-friendly touch-screen interface that stores multiple parameter settings. This makes it ideal for factories with varied product lines or frequent order changes.

To meet different output needs, the machine supports a wide speed range. Small packaging sizes can reach high production speeds, while larger or heavier dried fish products maintain excellent measuring accuracy even at moderate speeds. The built-in error-correction function monitors each cycle and automatically adjusts weight deviations to ensure stable, reliable packaging throughout the day.

Safety features—including overload protection, emergency stop systems, and temperature-controlled sealing modules—ensure smooth and secure operation. When the machine detects abnormalities such as insufficient film, sealing temperature errors, or bag-opening issues (for premade pouch types), it automatically stops and alerts the operator. This helps avoid film waste and prevents unqualified bags from reaching the market.

Customization options are available to match your dried seafood product line: date printers, label applicators, hole-punchers, gusset devices, zipper-opening functions, vacuum sealing modules, and nitrogen flushing systems. Each optional upgrade is designed to further optimize packaging performance and improve the competitiveness of your product in domestic and overseas markets.

Whether you export dried anchovies to Asia, supply dried squid snacks to supermarkets, or process specialty seafood for gourmet stores, our Dried Fish Packaging Machine provides the consistency, efficiency, and professional packaging quality your business needs. By automating your production, you can reduce labor costs, maintain product hygiene standards, and increase daily output, helping your company scale production and improve factory efficiency.

This machine is a practical long-term investment for any seafood processing plant. With stable performance, versatile functions, and strong after-sales support, it will help your products stand out with clean, appealing, and retail-ready packaging. From product protection to efficiency and branding value, this system delivers a complete solution for dried fish and dehydrated seafood packaging.

| Item | Specification |

|---|---|

| Machine Type | Vertical Form Fill Seal Machine / Premade Pouch packing machine |

| Applicable Products | Dried fish, dried anchovies, shredded squid, fish strips, dried seafood snacks |

| Weighing System | Multihead weigher / linear weigher (customizable) |

| Packing Speed | 20–60 bags/min (depending on product & bag size) |

| Bag Types | Pillow bag, gusset bag, flat pouch, stand-up pouch, zipper pouch |

| Bag Size Range | Width 80–250 mm; Length 100–350 mm |

| Film Material | PET/PE, OPP/CPP, Nylon/PE, aluminum laminated film |

| Film Thickness | 60–120 microns |

| Film Roll Width | 180–520 mm (optional up to 720 mm) |

| Filling Accuracy | ±0.2–1 g (based on product weight) |

| Power Supply | AC 220V / 380V, 50/60Hz |

| Total Power | 2.2–4.5 kW (based on configuration) |

| Air Consumption | 0.6 MPa, 0.4 m³/min |

| Machine Frame | SUS304 food-grade stainless steel |

| Control System | PLC + Touch Screen (multiple language menus) |

| Sealing System | Vertical + horizontal heat sealing with temperature control |

| Optional Functions | Nitrogen flushing, date printer, hole punching, label applicator, vacuum sealing, zipper forming |

| Overall Dimensions | Approx. 1400×1200×1600 mm (varies by model) |

| Machine Weight | 450–650 kg |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.