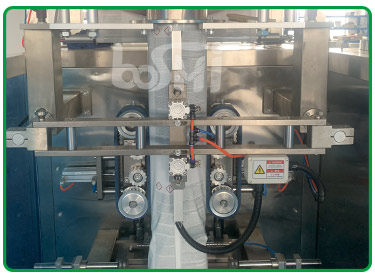

adopts advanced PLC plus photoelectric control system.,adjusted touch screen.

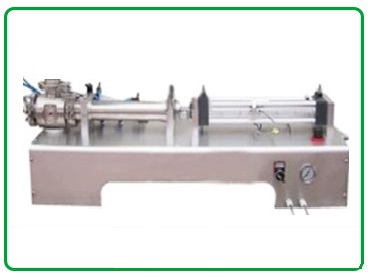

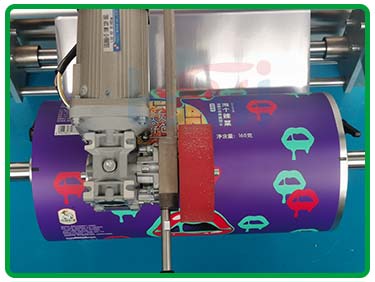

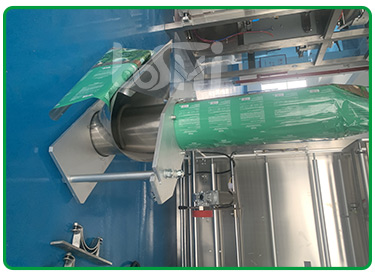

It can automatically complete the processes of measuring, bag making, filling, sealing, cutting, printing the production date, and cutting easy to tear. through the rotor Pump feeding, precise metering of packaging system.

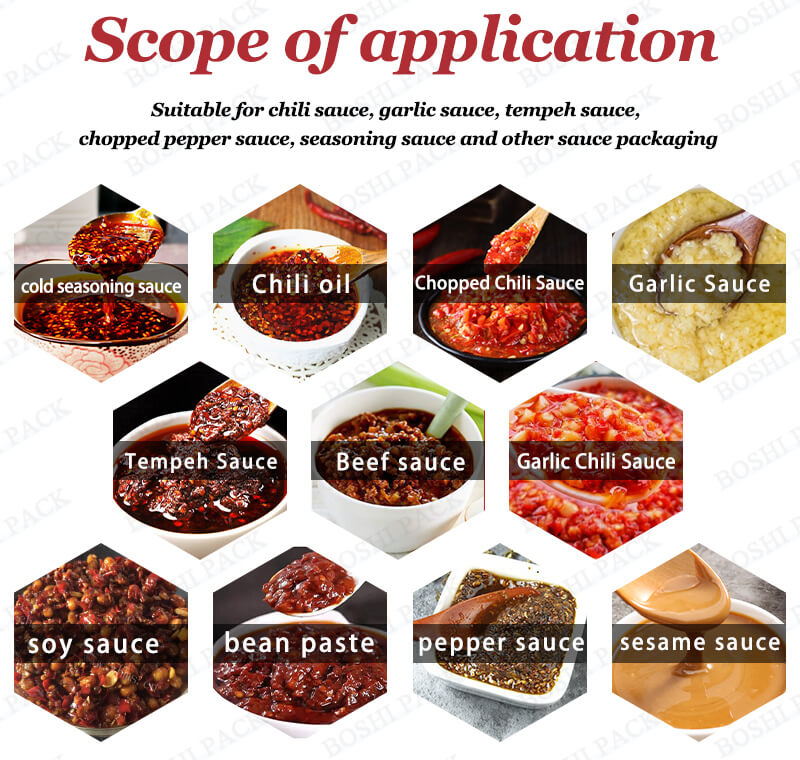

Touch screen can control grams,more convenient to use.This machine can be used for automatic packaging of various liquid and paste-like items in food, chemical, daily chemical and other industries, such as:

Baking category: butter, salad dressing, cheese, custard, egg liquid, etc.;

Fillings: lotus seed paste, bean paste, pineapple, winter paste, etc.;

Sauce: tomato sauce, sesame sauce, chili sauce, strawberry sauce, durian sauce and other jams;

Beverages: scented tea, coconut fruit, jelly, ice cream syrup and other tea ingredients;

Chinese food: dry yellow sauce, chili oil, hot pot oil, peanut butter, sesame sauce, porridge, soy milk, meat filling, shrimp slip, etc.;

Western food: curry sauce, meat sauce, satay sauce, chocolate sauce, etc.;

Glue: wallpaper glue, jelly glue, rice glue, construction glue, etc.;

Greases: lithium-based grease, beauty paraffin, beeswax, industrial additives, etc.