Fresh snail/chicken/shrimp/fish ball

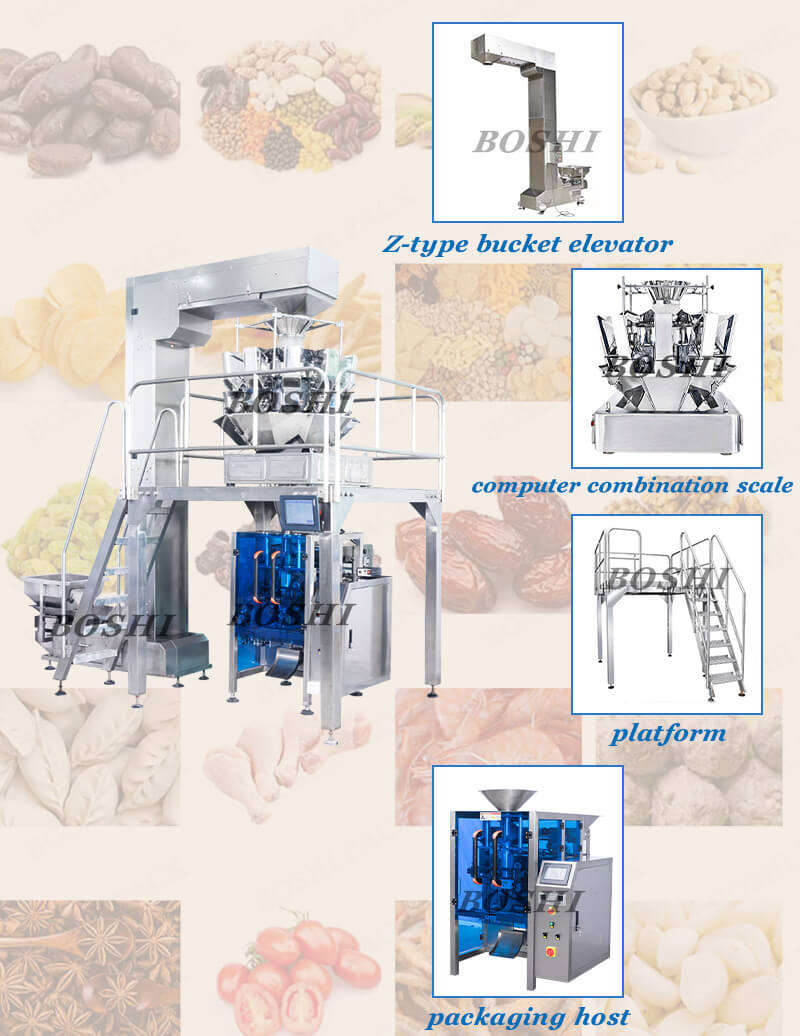

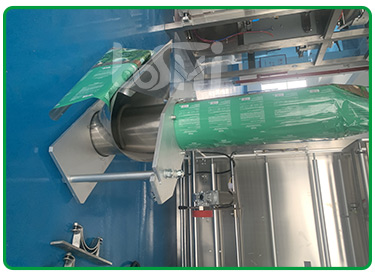

Packaging Machine is an automated packaging equipment designed for fresh meatball foods with high moisture content and easy to deteriorate. Its core features are efficient preservation, anti-adhesion design, precise metering and high hygiene standards. The following is an analysis of the specific features:

1. Efficient preservation and extended shelf life

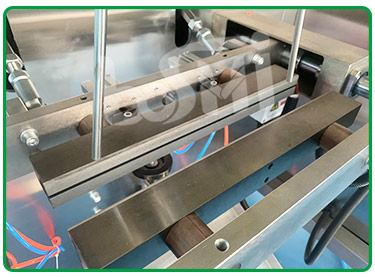

Integrated modified atmosphere packaging (MAP): nitrogen, carbon dioxide and other mixed gases can be injected to inhibit the growth of microorganisms, maintain the color and elasticity of meatball foods, and extend the shelf life by 1-2 times.

Rapid cooling system: After packaging, the product is quickly cooled through cold air circulation or water cooling tunnel to lock in the freshness and reduce the generation of condensed water.

2. Anti-adhesion and flexible processing

Non-contact filling: The chute or free-falling design is adopted to avoid deformation or surface damage of meatballs caused by mechanical extrusion.

Anti-stick coating hopper: Food-grade Teflo or ceramic coating silo reduces the adhesion residue of high-moisture meatballs.

Vibration-assisted dropping: Controllable vibration is used to ensure that the meatballs are evenly arranged to avoid loose packaging seals caused by stacking.

3. Accurate metering and efficient production

Multi-mode metering system:

Weighing type: dynamic weighing error ≤±1%, suitable for mixed specifications or large packaging (such as 500g family pack).

Volumetric type: high-speed counting and filling, up to 80-150 packages per minute, suitable for standardized small specifications (such as 10 capsules/pack).

Dual-station synchronous operation: some models support synchronous weighing and filling, and the production capacity is increased by more than 30%.

Automatic feeding function: automatic alarm and pause when the silo is out of material, reducing the empty package rate.

4. High hygiene standards and easy-to-clean design

Fully enclosed stainless steel structure: the contact surface complies with FDA/EC food grade certification, corrosion-resistant and has no sanitary dead corners.

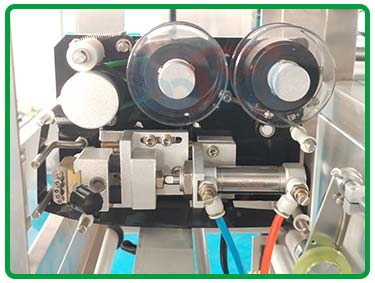

CIP online cleaning system: one-button start of the circulation flushing of the pipeline and silo, suitable for high-pressure water guns or food-grade cleaning agents.

Anti-cross contamination design: independent conveying channels (such as split hoppers) support the simultaneous processing of different categories such as snail balls and chicken balls to avoid flavor mixing.

5. Flexible adaptation to diverse needs