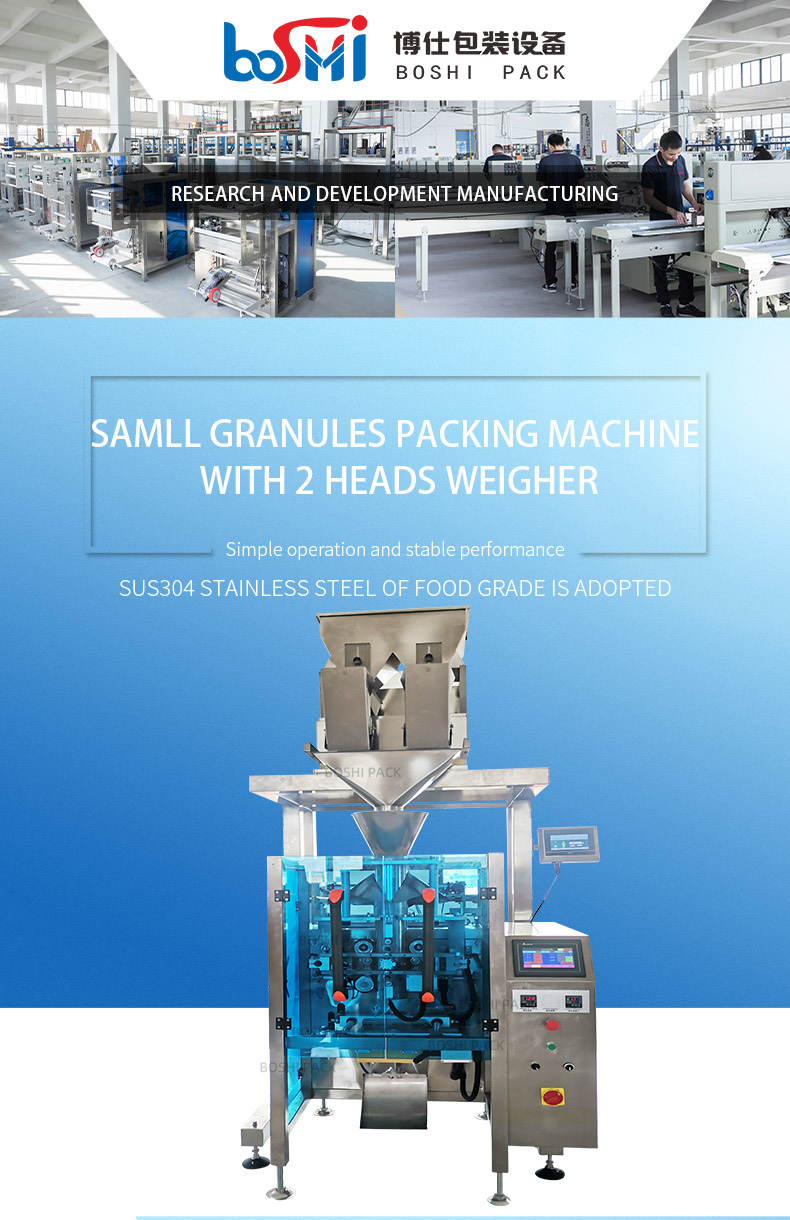

Salt Nuts Beans Cooked Rice Sugar Packing Machine

$99991-4 Set/Sets

$85995-9 Set/Sets

$5990≥10Set/Sets

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FAS |

| Transportation: | Ocean,Land,Air |

| Port: | FOSHAN |

FOSHAN BOSHI PACKING MACHINERY CO.,LTD

$99991-4 Set/Sets

$85995-9 Set/Sets

$5990≥10Set/Sets

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FAS |

| Transportation: | Ocean,Land,Air |

| Port: | FOSHAN |

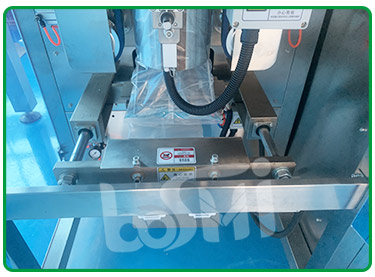

Model No.: BS-420G-2

Brand: BOSHI

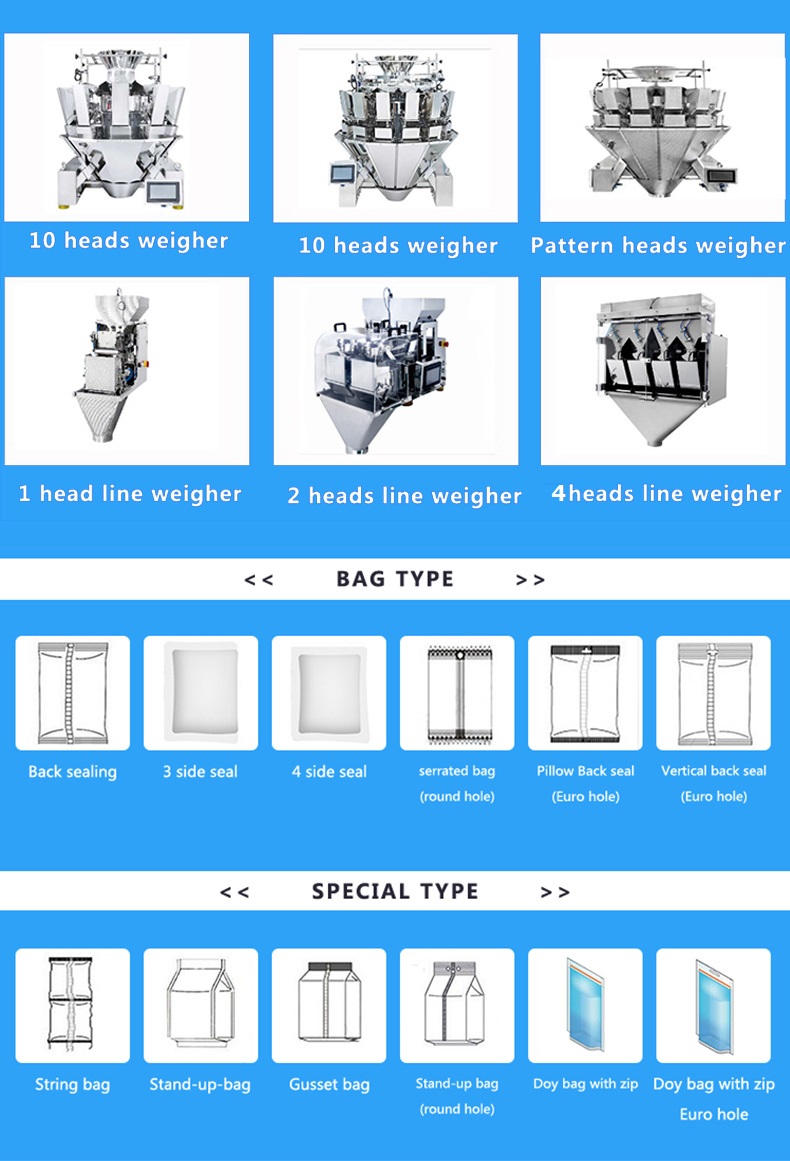

Production Capacity: 20bag/min, 40bag/min, 25bag/min, 15bag/min, 10bag/min, 50bag/min, 30bag/min

Weight (KG): 400

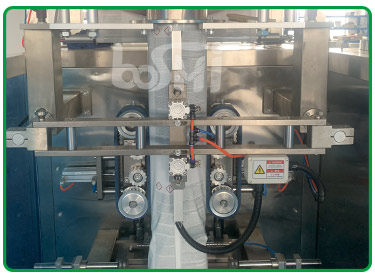

Function: Wrapping, Labeling, Sealing, Date Printing

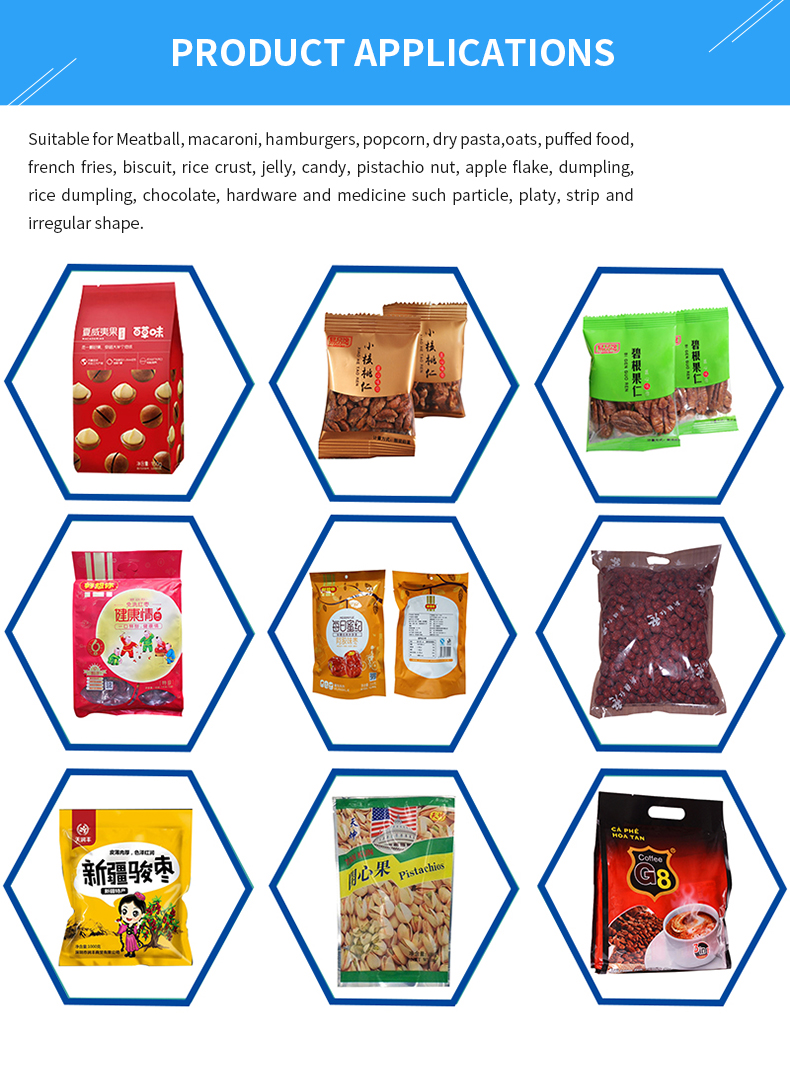

Application: Food

Voltage: 220/380V

Dimension(L*W*H): L 1350 * W 1000 * H 1400 mm

Warranty: 1 Year

Core Components: Motor

Model: BS-420G-2

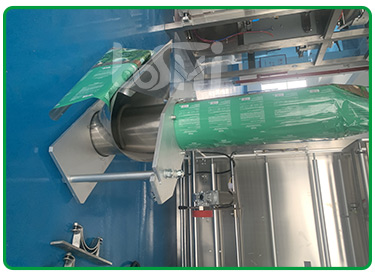

Film Width: Max.420mm

Film Thickness: 0.03-0.1mm

Bag Width: 50-200 mm

Bag Length: 50-300 mm

Packing Speed: 10-70 bags/ min

Type Of Sealing: Pillow bag or gusset bag

Packing Material: OPP/CPP, OPP/CE,PET/PE etc.

Air Consumption: 0.65 mpa

Gas Consumption: 0.3 cubic meter/ min

Warranty Of Core Components: 1 Year

| Selling Units | : | Set/Sets |

| Package Type | : | 3 plywood wooden box packaging |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.