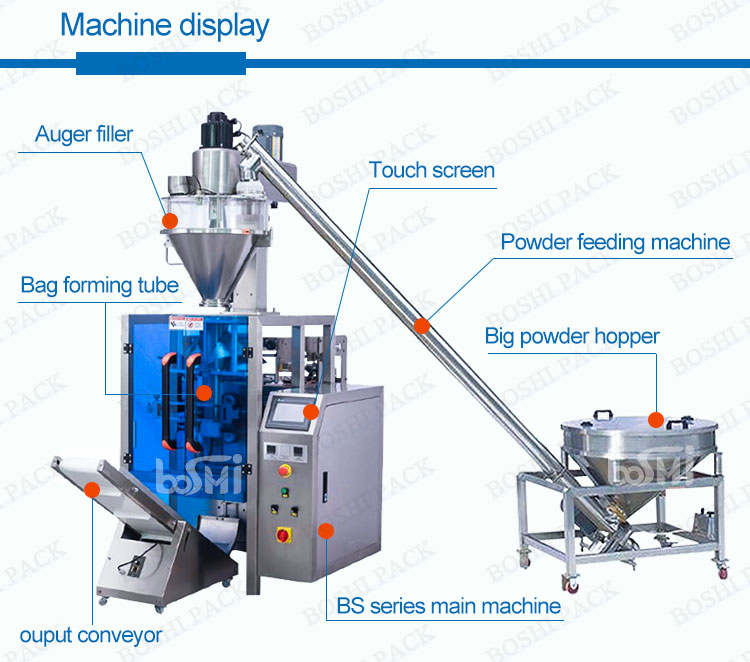

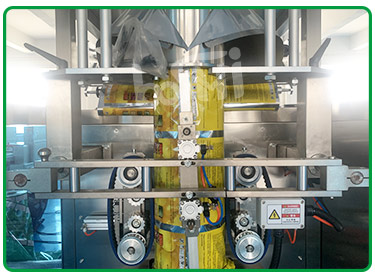

Tea Powder & Flour Packaging Machine - Automatic Vertical 100g to 1kg

Get Latest Price| Min. Order: | 1 set |

| Min. Order: | 1 set |

Weight (KG): 600

Function: FILLING, Wrapping, Labeling, Sealing, Date printing

Application: Food

Packaging Type: Stand-Up Pouch, Bags, Film, Foil, Pouch

Packaging Material: Plastic, Paper

Automatic Grade: Automatic

Driven Type: Pneumatic

Voltage: 220/380V

Place Of Origin: Guangdong, China

Brand Name: BOSHI POWDER FLOUR PACKING MACHINE

Dimension(L*W*H): L 1320 * W 920 * H 1392 mm

Warranty: 1 Year

Key Selling Points: High-Accuracy

Machinery Test Report: Provided

Video Outgoing-inspection: Provided

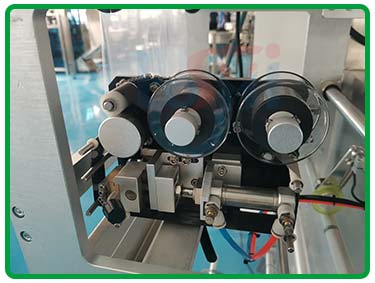

Core Components: Motor

After-sales Service Provided: Video technical support, Online support, Free spare parts

Model: BS-420P

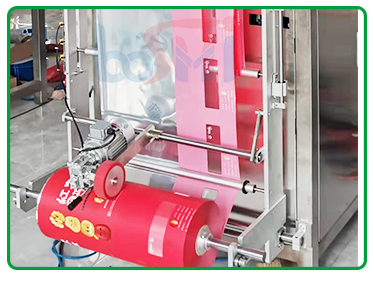

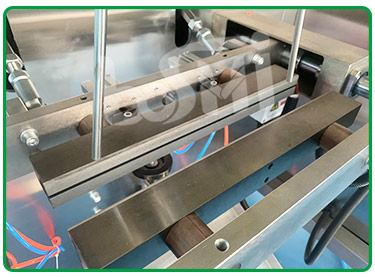

Film Width: Max.420mm

Film Thickness: 0.03-0.1mm

Bag Width: 50-200 mm

Bag Length: 50-300 mm

Packing Speed: 10-70 bags/ min

Type Of Sealing: Pillow bag or gusset bag or quad side seal

Packing Material: OPP/CPP, OPP/CE,PET/PE etc.

Air Consumption: 0.65 mpa

Gas Consumption: 0.3 cubic meter/ min

| Selling Units | : | set |

The file is encrypted. Please fill in the following information to continue accessing it

| Model | BS-420P | |

| Film width | Max.420mm | |

| Film thickness | 0.03-0.1mm | |

| Bag width | 50-200 mm | |

| Bag length | 50-300 mm | |

| Packing speed | 10-70 bags/ min | |

| Type of sealing | Pillow bag,3 or 4 side seal and gusset bag | |

| Packing material | OPP/CPP, OPP/CE,PET/PE etc. | |

| Air consumption | 0.65 mpa | |

| Gas consumption | 0.3 cubic meter/ min | |

| Machine dimensions | 1080*1300*1400 mm | |

| Machine weight | 600 kg | |

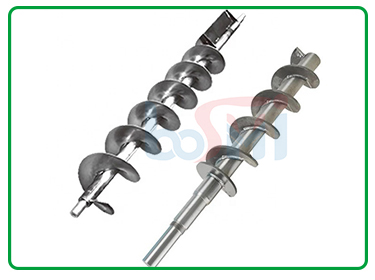

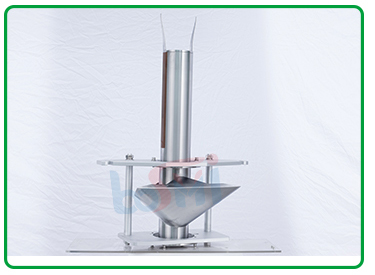

| Auger filler | | |

| Weighting and filling system | Auger screw | |

| Weighting range | 10-5000g (Different product have different weighting range ) | |

| Accuracy: | Volume<100g.Bias:0.5-1gVolume:100-5000g.Bias:0.5%-1% | |

| Filling speed: | 10-60 bags/min | |

| Filler hoper volume | 50 L | |

| Total power: | 1.5 kw | |

| Weight | 200KG | |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.